What Industries Need Water Treatment Systems Most? 8 Water-Dependent Sectors

Posted on October 30, 2019

Water quality isn’t optional for modern industries – it’s mission-critical. With 80% of manufacturing processes requiring treated water and regulatory standards tightening globally, certain industries simply cannot operate without reliable water treatment systems.

Quick Answer: Top 8 Industries That Depend on Water Treatment

- 1. Healthcare & Pharmaceuticals – Strictest purity requirements

- 2. Food & Beverage – Product safety and taste consistency

- 3. Power Generation – Massive consumption for cooling/steam

- 4. Electronics & Semiconductors – Ultrapure water for chip manufacturing

- 5. Chemical Manufacturing – Process water for reactions

- 6. Textile Industry – High-volume dyeing and finishing

- 7. Pulp & Paper – Water recycling and bleaching

- 8. Metal Processing – Surface treatment and cooling

Why These Industries Can’t Survive Without Water Treatment

Regulatory Compliance: FDA, EPA, and international standards mandate specific water quality levels. Non-compliance = hefty fines and shutdowns.

Product Quality: Contaminated water ruins entire production batches. Even trace impurities affect taste, safety, and shelf life.

Equipment Protection: Untreated water causes $2.8 billion in annual equipment damage through corrosion and scaling.

Cost Savings: Treatment systems reduce operational costs by 15-30% through recycling and prevented damage.

1. Healthcare & Pharmaceuticals: Zero Tolerance for Contamination

Water Usage: 50-100 gallons per hospital bed daily

Why Critical: Pharmaceutical water must meet USP standards with zero viable microorganisms

Key Applications:

- Drug manufacturing (Water for Injection)

- Medical device sterilization

- Dialysis treatment (AAMI standards)

- Laboratory testing

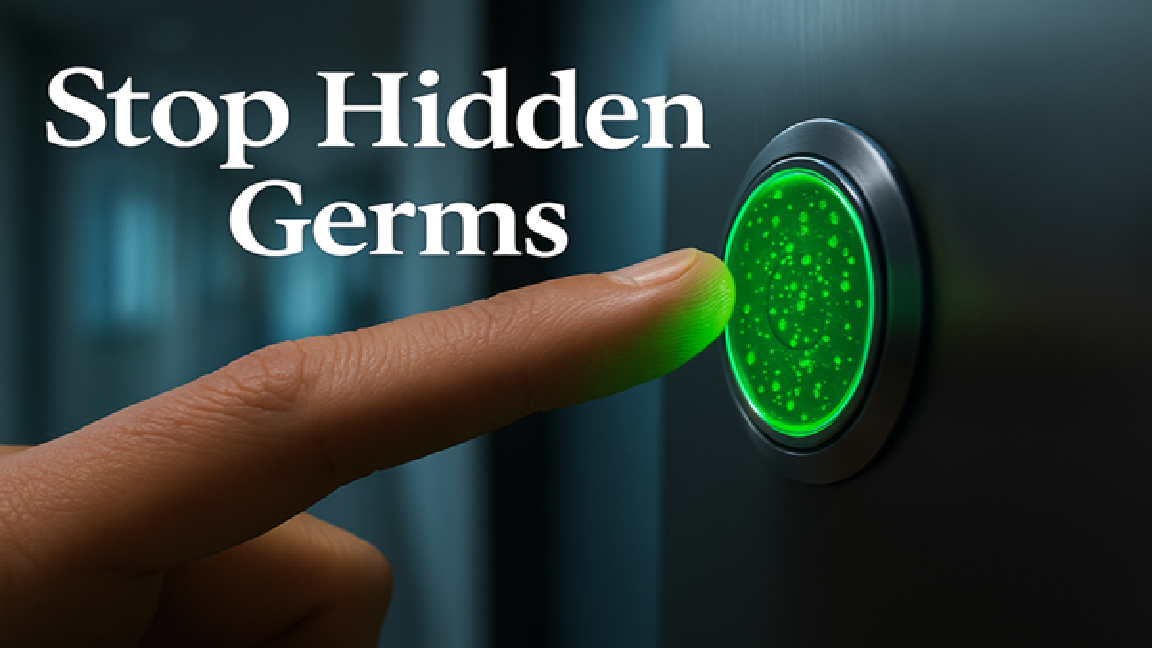

Treatment Tech: Reverse osmosis + UV sterilization + electrodeionization

Bottom Line: One contamination incident can shut down entire pharmaceutical operations and endanger patient lives.

2. Food & Beverage: Water IS the Product

Water Usage: 2-10 gallons per gallon of product

Why Critical: Water comprises 70-95% of most beverages and directly affects taste/safety

Key Applications:

- Beverage production (Coca-Cola uses 2.7L water per 1L product)

- Dairy processing (2-3 gallons per gallon of milk)

- Meat processing (USDA bacterial standards)

- Fresh produce washing

Treatment Tech: Chlorine dioxide + activated carbon + UV disinfection

Bottom Line: Poor water quality = product recalls and foodborne illness outbreaks.

3. Power Generation: Biggest Industrial Water Consumer

Water Usage: 25,000-60,000 gallons per MWh generated

Why Critical: 41% of all US water withdrawals go to power generation

Key Applications:

- Steam turbine feed water (ultrapure required)

- Cooling tower operations

- Nuclear reactor cooling (strictest requirements)

- Emissions control systems

Treatment Tech: Demineralization + reverse osmosis + biocide treatment

Bottom Line: Poor water quality reduces plant efficiency by 15-25%, costing millions in lost revenue.

4. Electronics & Semiconductors: Purest Water on Earth

Water Usage: 4-6 gallons per wafer processed

Why Critical: One 0.1-micron particle can destroy an entire microprocessor

Key Applications:

- Silicon wafer cleaning

- Chemical dilution for etching

- Final rinse before packaging

Treatment Tech: Multi-stage RO + electrodeionization + UV + ultrafiltration

Bottom Line: Semiconductor water must be 1,000x purer than drinking water.

5. Chemical Manufacturing: Process-Critical Water

Water Usage: 1-50 gallons per pound of product

Why Critical: Water often acts as reactant, not just solvent – quality affects chemical reactions

Key Applications:

- Chemical synthesis reactions

- Product washing and separation

- Reactor cooling

- Safety wash systems

Treatment Tech: Ion exchange + activated carbon + advanced oxidation

Bottom Line: Trace metal contamination can trigger dangerous reactions or create toxic byproducts.

Industry Water Consumption: The Scale

- Power Generation: 161 billion gallons daily (US)

- Food & Beverage: 1.15 trillion gallons annually (global)

- Healthcare: 150 billion gallons annually (US)

- Electronics: 2.2 billion gallons annually (semiconductors)

- Textiles: 79 billion cubic meters annually (global)

The Cost of Poor Water Quality

Equipment Damage: $2.8 billion annually across US industries

Food Industry Losses: $14 billion annually in recalls and waste

Average EPA Fine: $18,000 per violation (some exceed $1 million)

Energy Waste: 15-25% increase from scaling and fouling

Downtime: 72 hours average per water-quality incident

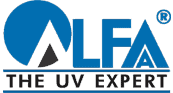

Which Treatment Technology by Industry?

High-Purity Needs (Healthcare, Electronics): Multi-stage RO + EDI + UV

Food Safety Focus: Filtration + UV + chlorine dioxide

High-Volume Users (Power, Paper): Clarification + softening + biocide

Custom Applications (Chemical, Metal): Ion exchange + specialized filtration

Future Trends Driving Treatment Demand

Tighter Regulations: Standards become stricter annually

Water Scarcity: Forces recycling and reuse systems

Sustainability Pressure: Zero liquid discharge requirements

Smart Technology: IoT monitoring and AI optimization

Bottom Line: Water Treatment = Business Insurance

Industries don’t choose water treatment – they need it to survive. The question isn’t whether to invest, but which system best fits your specific requirements.

Key Benefits:

- ☑Regulatory compliance and legal protection

- ☑Consistent product quality

- ☑Extended equipment life

- ☑Lower operational costs through recycling

- ☑Environmental sustainability

Investment Reality: Water treatment systems typically pay for themselves within 2-3 years through prevented damage, reduced waste, and operational savings.

For industries evaluating options, the smartest approach is consulting with water treatment specialists who understand your specific regulatory requirements and operational needs. The cost of proper treatment is always less than the cost of poor water quality.